Assembly

Assembly of plastic assemblies - precision and quality from a single source

Bebusch Hungária Kft. is your reliable partner in plastic injection molding and the assembly of plastic components. With state-of-the-art technology and extensive experience, we offer precise and ready-to-install solutions for a wide range of applications. In addition to assembly, our service portfolio also includes supplementary processes such as soldering, pad printing and comprehensive quality testing.

Efficient component assembly for the highest demands

Our assembly processes are specially designed to connect plastic components quickly and precisely to form complete assemblies. In doing so, we rely on modern assembly techniques that guarantee high reproducibility and consistent quality. The assemblies we produce are used in a wide range of industries - from the automotive industry to electrical engineering and medical technology.

Supplementary processes for functional end products

In addition to pure assembly, we offer supplementary processes to optimize the functionality and optical quality of our assemblies:

- Soldering: our precise soldering processes enable reliable electrical connections in assemblies with integrated electronic components.

- Pad printing: We refine plastic parts with high-quality pad printing, which ensures permanent and precise markings.

- Testing: To ensure the highest quality and reliability, our assemblies undergo extensive testing procedures, including mechanical stress tests, electrical function tests and visual inspections.

Your partner for customized solutions

Thanks to our many years of experience in plastic injection moulding and component assembly, we can implement tailor-made solutions for individual customer requirements. Our production processes are flexible, efficient and geared to the highest quality standards.

Rely on Bebusch Hungária Kft. as your competent partner for the assembly of plastic components - from individual components to complete system solutions.

Rely on Bebusch Hungária Kft. as your competent partner for the assembly of plastic components - from individual components to complete system solutions.

Inquiry about injection molding

Soldering

Manual assembly

Pad printing

Testing

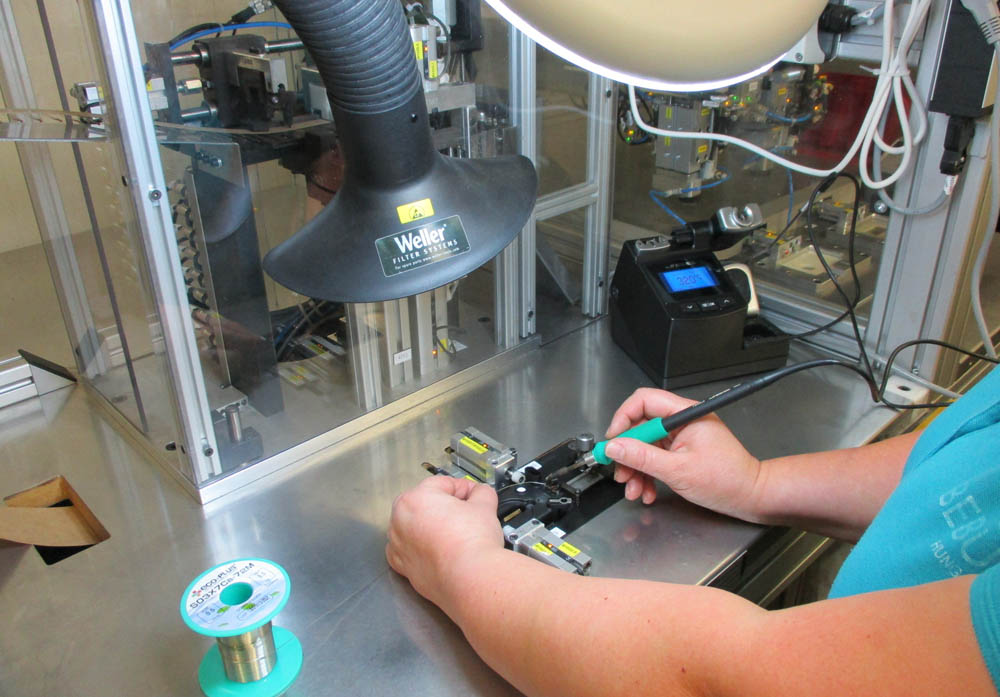

Soldering

Precise soldering for reliable electrical connections

Soldering is an essential process for creating safe and durable electrical connections in plastic assemblies. Our modern soldering processes guarantee a precise and reliable connection of electronic components. Thanks to high process control and optimal material selection, we achieve consistently high quality.

The combination of plastic injection molding and soldering technology enables the production of ready-to-install assemblies from a single source. Bebusch Hungária Kft. stands for precise processing and maximum reliability in component assembly.

The combination of plastic injection molding and soldering technology enables the production of ready-to-install assemblies from a single source. Bebusch Hungária Kft. stands for precise processing and maximum reliability in component assembly.

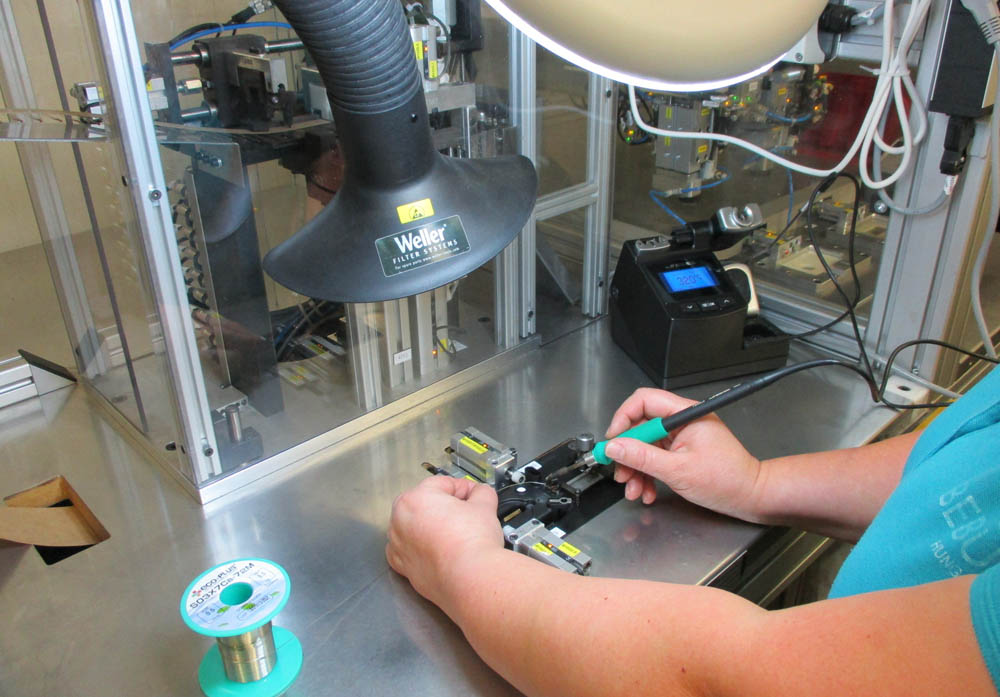

Manual assembly

Flexibility and precision for plastic assemblies

Our manual assembly enables the precise and flexible connection of plastic components to form ready-to-install assemblies. Specially trained employees ensure the highest quality, even for complex or sensitive components. This method is particularly suitable for small series, custom-made products and assemblies with special requirements.

By combining plastic injection molding and manual assembly, we offer tailor-made solutions for a wide range of industries. Bebusch Hungária Kft. stands for quality, efficiency and reliable component assembly from a single source.

By combining plastic injection molding and manual assembly, we offer tailor-made solutions for a wide range of industries. Bebusch Hungária Kft. stands for quality, efficiency and reliable component assembly from a single source.

Pad printing

Precise and permanent marking of plastic parts

Pad printing enables high-quality and durable printing of plastic parts with fine details and high ink adhesion. Thanks to state-of-the-art printing technologies, we can produce razor-sharp logos, symbols and technical markings on differently shaped surfaces.

This process is particularly suitable for components with complex geometries or areas that are difficult to access. By combining plastic injection molding and pad printing, we offer our customers tailor-made and ready-to-install solutions. Bebusch Hungária Kft. stands for precision, quality and consistent printing results.

This process is particularly suitable for components with complex geometries or areas that are difficult to access. By combining plastic injection molding and pad printing, we offer our customers tailor-made and ready-to-install solutions. Bebusch Hungária Kft. stands for precision, quality and consistent printing results.

Testing

Quality assurance for reliable plastic parts

To ensure the highest quality and functional reliability, our assemblies undergo comprehensive testing procedures. These include mechanical load tests, electrical function tests and visual inspections.

Using state-of-the-art measurement technology, we detect deviations at an early stage and ensure that each assembly meets the required specifications. The combination of plastic injection molding and strict quality controls guarantees durable and precise components. Bebusch Hungária Kft. stands for reliable test procedures and the highest quality standards in component assembly.

Using state-of-the-art measurement technology, we detect deviations at an early stage and ensure that each assembly meets the required specifications. The combination of plastic injection molding and strict quality controls guarantees durable and precise components. Bebusch Hungária Kft. stands for reliable test procedures and the highest quality standards in component assembly.

Inquiry form

- Just send us a short message and we will be happy to answer your questions by phone or e-mail.